Krishna Engineering Works, India dealing on manufacturing and exporting door wrapping machine from India. We have designed Door Wrapping Machine to wrap with a wide variety of window and door products. Our rich experience has given us the opportunity to design quality with meeting International standard. Heavy duty Rubber Roller for flexible packaging machinery and Pallet Wrapping Machine

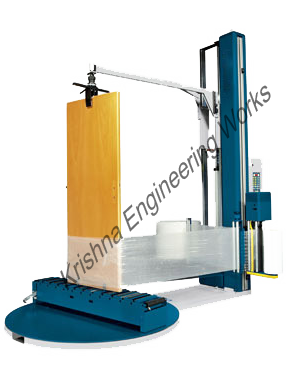

Door Wrapping Machine

STANDARAD FEATURES

- Fully Automatic Machine.

- Heavy duty turn table for all industrial applications.

- Sturdy mast and machined guide ways for guiding the stretch unit.

- Compact stretch unit with change gears to vary stretch percentage.

- Suitable for a wide range of stretch film material.

- Modular in construction

Product Description

Features:

- Adjustment of overlapping is possible by adjusting linear speed of conveyor- from control panel.

- Stretch Film is Cheaper Then other packing material.

- At Starting Point & ending Point – No of Wrap can be adjusted by from control panel.

- Speedy Pack & Labor Saving

- Wrap with papar and plastic

Application:

- Cable Tray.

- Alluminium section.

- Pvc Pipe.

- Door Panels

- Window panels

Specification:

- Rotary Disc Inside Dia: 700 mm

- Rotary Disc Speed : 18 Turns/Min

- Infeed & Out feed conveyor 2130 (L) x 500 (belt-W)MM

- Power Supply : Three Phase With Neutral 440V/50HZ

- Electrical Power : 2 HP

- Air Requirement: 0.5 CFM @ 6 Bar Pressure

- Conveyor Speed : 2 to 8 Mtr/min. Variable AC Drive

- Max. LLDEP Stretch Film Roll width : 250 mm

- LLDEP-Stretch Film Roll Core Dia : 75 mm

- Working Height : 750 mm

- Product Holding : Pneumatically Operated Roller Frame at both side.

TECHNICAL SPECIFICATION

CAPACITY |

|

|

Pallets/Hour

|

15-30 pallets/hour

|

|

Pallet Size

|

1150 x 1150 (44″ x 44″)

|

|

Pallet Height

|

2500 mm (100″)

|

|

Weight / Pallet

|

2000 Kg

|

Machine |

|

|

Height (above GL)

|

350 mm

|

|

Speed

|

50 meters/minute

|

|

Maximum stretch

|

300%

|

|

Installed power

|

1.5 kW

|

|

Power supply

|

220V, Single phase, 50Hz

|

Film Details |

|

|

Material

|

LLDPE – Stretch Film

|

|

Film width

|

250 to 500 mm

|

|

Film thickness

|

12-35 µ (23µ recommended)

|

|

Core diameter

|

76 mm

|

|

Maximum film diameter

|

250 mm

|

|

Max. weight of film roll

|

15 kgs

|